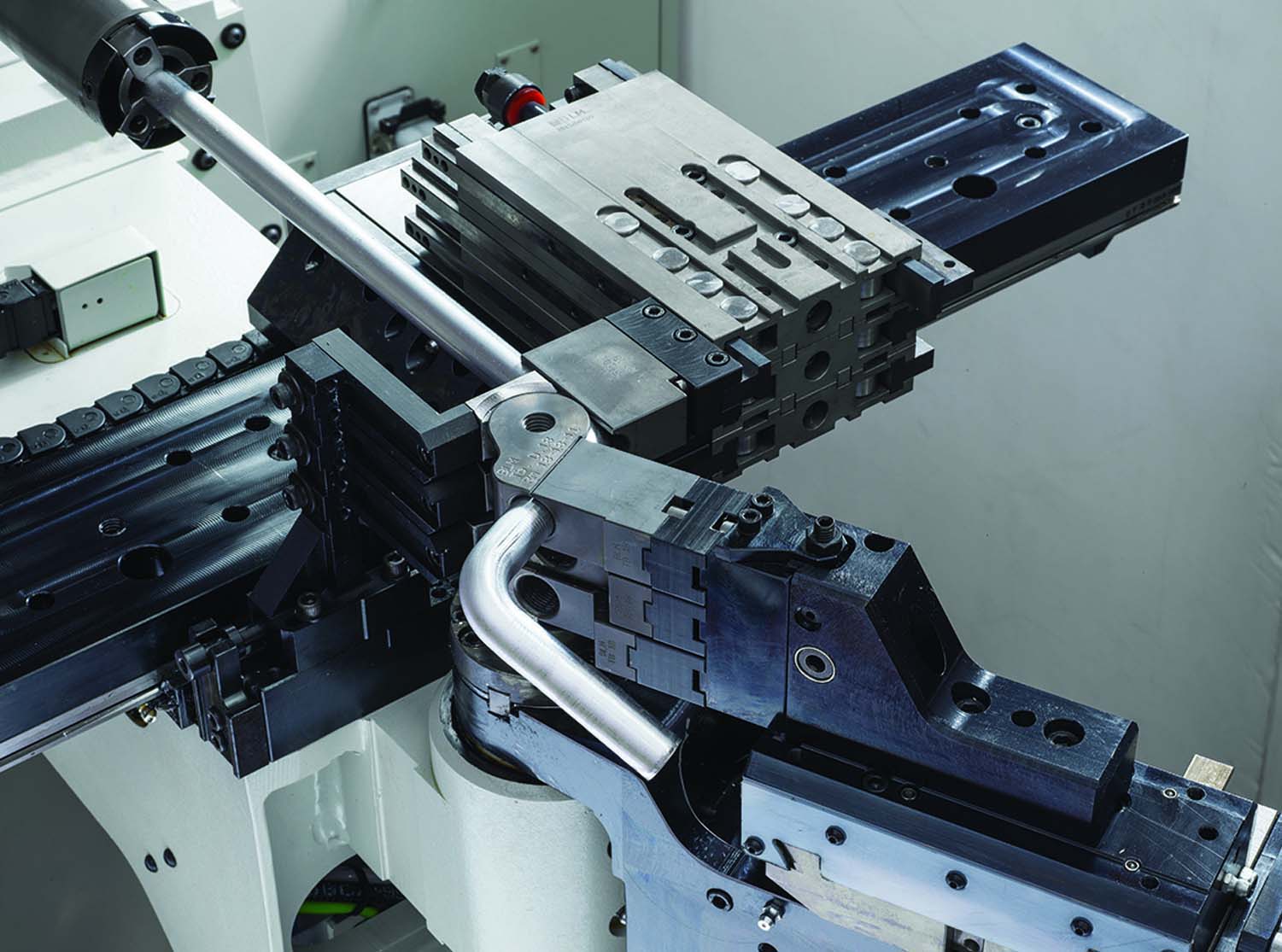

BCF continues to invest in the future of HVAC-R components and tubes introducing a new, technologically advanced tube bending machine to its production line, capable of processing diameters up to 150 mm.

Maximum precision

The new, fully electric, tube bending machine guarantees maximum precision and perfect repeatability, even for the most complex geometries. This translates into components of the highest quality, in compliant with the most stringent specifications.

Operational flexibility

Thanks to its incredible flexibility, this new technology allows BCF to respond quickly and efficiently to the requests of many customers in the industrial refrigeration and air conditioning sector.

Optimised efficiency and automatic parameters

The automatic and adaptive adjustment of bending parameters maximizes process efficiency. This approach accelerates production, significantly reduces the risk of errors, and reduces waste. As a result, parts are compliant from the very first run.

A strategic investment to better serve our customers

“This strategic investment, – comments Paolo Tonutti, Group Operations Director – demonstrates our ongoing commitment to providing customised and rapid solutions, responding effectively to the demands of all our customers in the HVAC-R tube processing sector.”